- Packs are created from a flat cardboard that is glued

- Ergonomic machines with good accessibility for production and maintenance staff

- Flexible machines with quick changeover times

- Stainless steel machine frames

- Driven by servo-motors and reduced maintenance

The benefits of Paker solutions

Questions ?

Contact us !

Tel. : +33 (0) 2 37 88 17 17

E-mail : paker@paker.fr

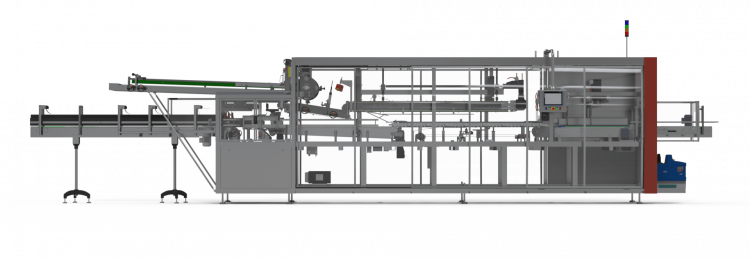

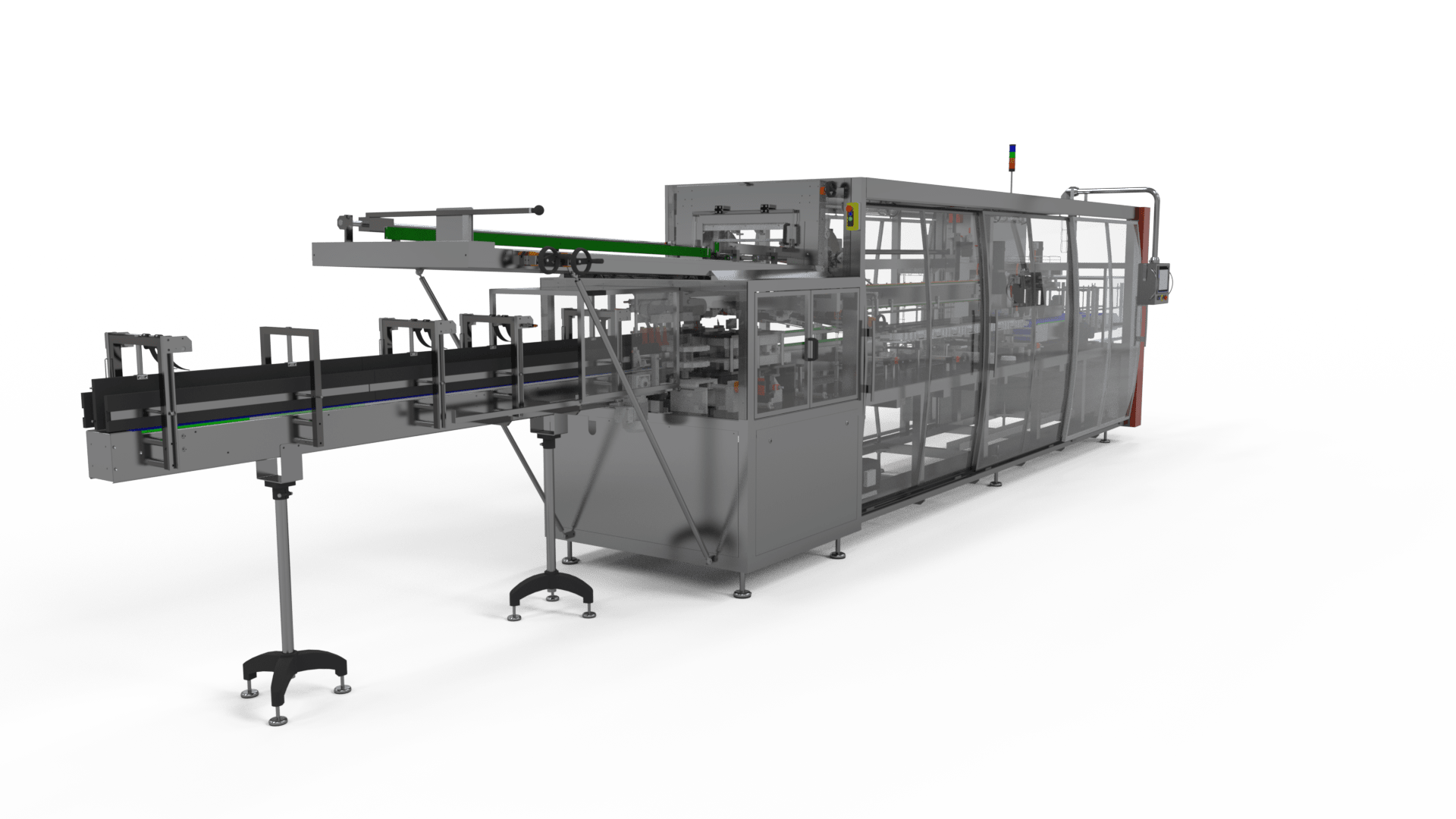

MB | C 12 - 9000

Continuous wrapping machine for packs of bottles, 9,000 packs/h (150 packs/min) | Glued underneath using a flat carton | Products in 1 layer over 1 or 2 rows

Description

“Multipack machine for grouping bottles using a flat cardboard, closed by gluing underneath.

This ensures great flexibility for daily operations, regardless of the dimensions of the products being grouped together or the type of packaging being used (cluster pack wraps, neck-through wraps, gussets etc.). The Paker solution also ensures great upgradeability over time, allowing new products and formats to be packaged as well.

All of the settings and control functions can be accessed directly on the control panel. Entirely controlled by servo motors (not a chain drive). The ergonomics of Paker machines have been specially designed to ensure ease of use for maintenance operations.”