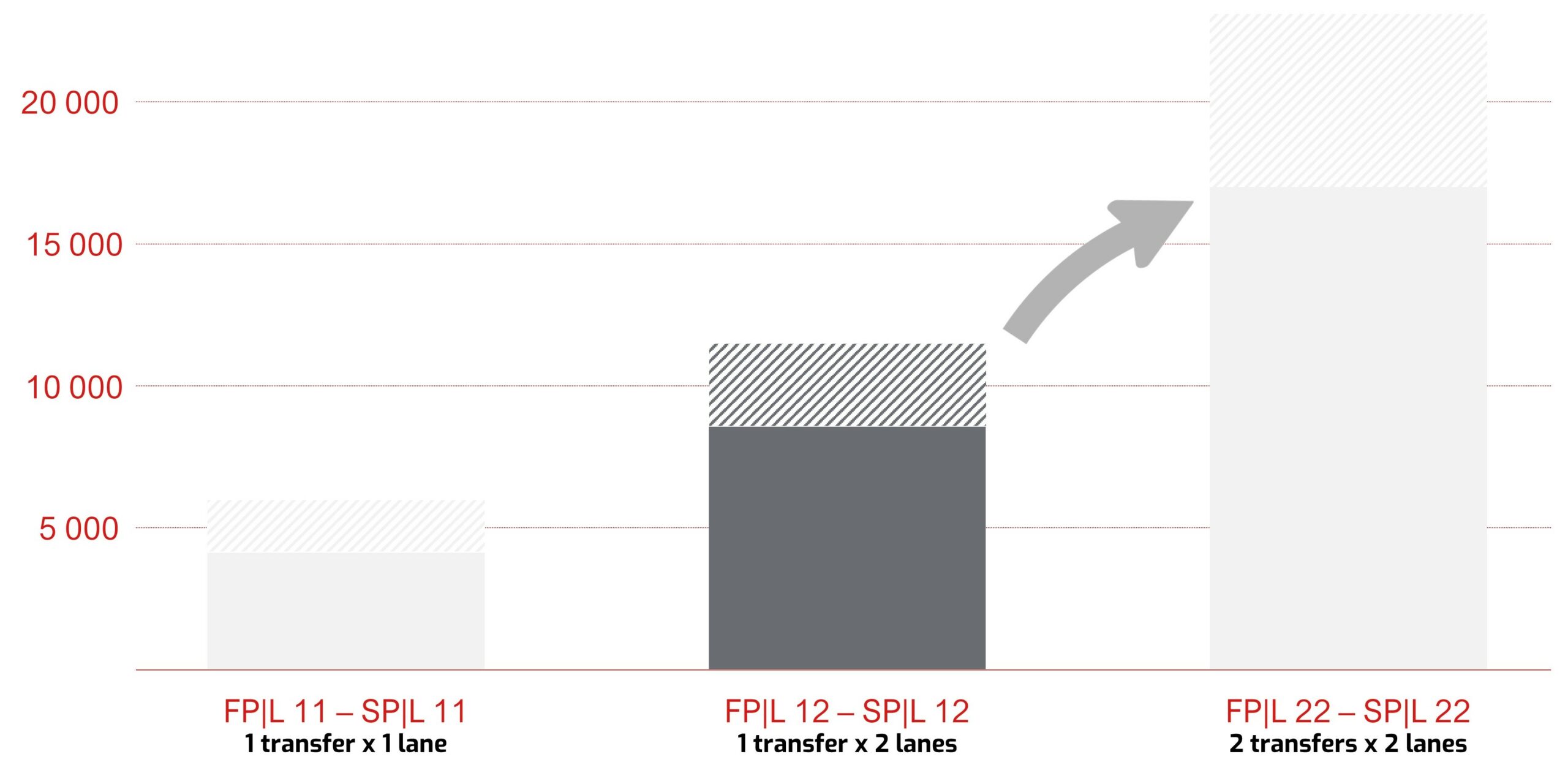

- Unique formats flexibility thanks to the SmartLine Transfer System

- Possibility to increase capacity as your needs are growing

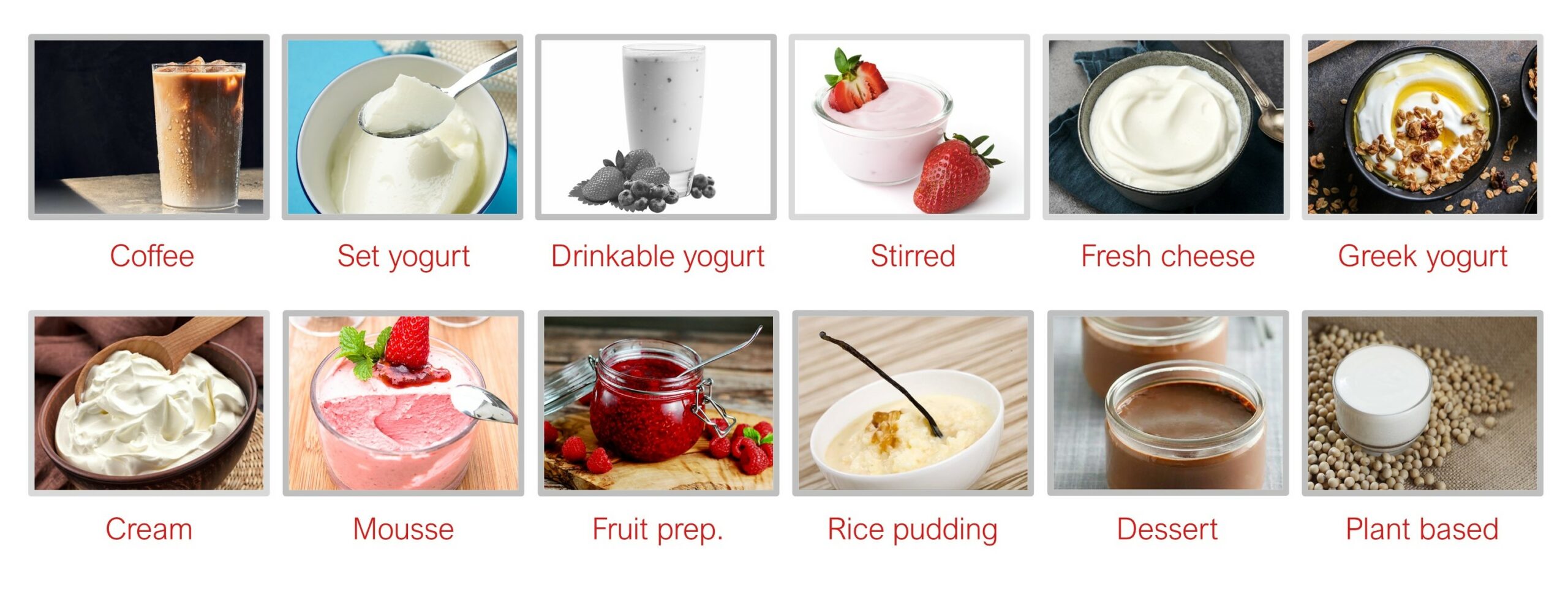

- Versatile dosing system : from very liquid (milk, probiotic) to very visquous (greek, fruit preparation)

- Felxible in terms of packaging materials

The benefits of Paker solutions

Questions ?

Contact us !

Tel. : +33 (0) 2 37 88 17 17

E-mail : paker@paker.fr

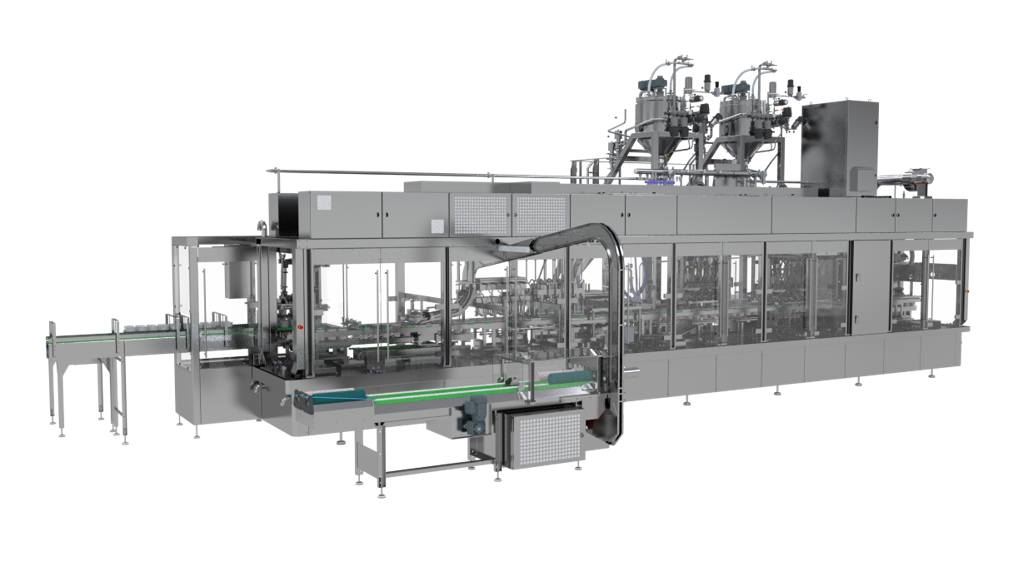

SmartLine Ultra Clean FP|L 12 or Aseptic SP|L 12

Linear Filling machine for Dairy and Plant based products, filled in cups and/or bottles.

Filler output

8 000 to 12 000 cups or bottles / h

1 transfer system with 2 lanes. Can evolve to 2 transfer systems equipped with 2 lanes each to bring the capacity to 16 000 to 24 000 cups or bottles per hour.

Description

Filling machine for sensitive cold chain or ambiant products. The SmartLine filler by PAKER has been designed with flexibility and the capacity to evolve in time. The flexibility and the ability to evolve enables SmartLine users to meet their ever transforming market demands.

Whether it is new products, new packaging formats, new packaging materials… your SmartLine filler adapts !

Applications and Packaging materials

Hygenic execution

Several packaging disinfection technologies are available on the SmartLine to achieve the desired log kill rate : UV lights, pulsed lights or Hydrogen peroxyde (H2O2).

Example of FPL|12 for carton cups and carton + plastic cups